Products

Contact us

Contact: Mr.liu

Mobile: +86-15141910330

Tel: +86-419-2261766

E_mail:sales@lnliantai.com

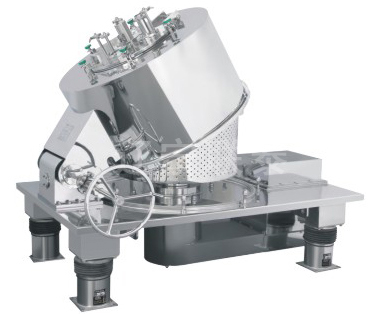

Current page: Home > ProductsFlat plate type upper discharge centrifuge

Main uses

This product can be used in solid-liquid separation of suspension liquid containing solid phase particles. It is especially suitable for separting flammable materials with high viscosity and fine particle size.

Main features

?♦ Flat structure, low center of gravity, and stable operation; four-point supporting, liquid damping, improve vibration isolating and vibration damping performance.

?♦ Frequency converter start, dynamic braking, PLC program control, touch screen, equipment failure self-diagnostic, automatic human-computer interface control, DCC control interface.

?♦ Transmission mechanism uses all-closed housing to prevent from dust pollution in transmission process.

?♦ Cosed construction with nitrogen protection system. Suitable for flammable and explosive occasions.

?♦ Full flip shell structure, the drum is exposed to facilitate cleaning and replacing filter cloth.

?♦ Centrifuge cavity is equipped with online cleaning device to prevent from cross contamination of products.

?♦ Surface roughness is as high as Ra0.2-0.4um and meets GMP standards.

?♦ Motor direct-drive, without friction dust caused by belt drive.

Configuration selection

?♦ Structure: full flip shell, full filp shell+full flip cover

?♦ Distribution mode: lateral districution tube and central distribution tube

?♦ Brake mode: energy consumption and feedback

?♦ Drive mode: belt and motor direct-drive

?♦ Shell turning assistance: manual, hydraulic, pneumatic

?♦ Motor drive: common motor, explosion-proof motor and variable frequency motor、

?♦ On-line cleaning: Shower ball and shower pipe

?♦ Transmission housing: Fully-closed and semi-closed

?♦ Electrical components: Brand supply

?♦ Surface treatment: mirror polishing, drawing and matting

?♦ Safety protection: nitrogen protection system, vibration protection, temperature protection, speed monitoring, overload protection and electromechanical interlocking

?♦ Nitrogen protection: automatic nitrogen charging device, oxygen content detection device, liquid seal device and gas-liquid separation device

Materials:

?♦ Stainless steel 304, 321, 316, 316L and Ti

?♦ Carbon steel or stainless steel coating PE, PP, HALAR (F30), PTFE (F4)

Technical parameters

|

Item |

PFSB600 |

PFSB800 |

PFSB1000 |

PFSB1250 |

|

Drum diameter (mm) |

600 |

800 |

1000 |

1250 |

|

Working volume of drum (L) |

45 |

100 |

140 |

320 |

|

Maximum loading capacity (kg) |

68 |

135 |

200 |

400 |

|

Drum speed (r/min) |

1500 |

1200/1500 |

1100/1200 |

1000 |

|

Maximum separation factor |

755 |

645/1007 |

650/805 |

698 |

|

Motor power(kW) |

3 |

5.5/7.5 |

11 |

18.5 |

|

Size (mm) |

1800*1200*1040 |

2000*1400*1085 |

2650*1600*1375 |

2900*1900*1500 |

|

Weight (kg) |

1500 |

2300 |

3200 |

5300 |