Technical support

Contact us

Contact: Mr.liu

Mobile: +86-15141910330

Tel: +86-419-2261766

E_mail:sales@lnliantai.com

Current page: Home > Selection and use of filter clothSelection and use of filter cloth

?♦ Selection and use of filter cloth

According to the physical and chemical properties of the separated materials, the choice and correct installation of appropriate filter cloth has a direct relationship with the separation effect, output, and vibration of the machine.

Filter cloth specifications are classified according to the filter mesh (air permeability). Determine according to the particle diameter of the separated material. Generally, in the selection of filter cloth, the bore diameter should be slightly larger than the diameter of the particles to be retained. In the initial stage, small particles pass the filter. When the larger particles retained form a cake layer, passage of particles can be eliminated, which improves the efficiency of filtration.

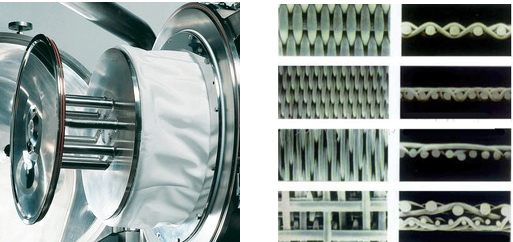

Single-wire double-layer composite filter cloth is recommended. The filter surface is treated by calendering to reduce the possibility of clogging and improve the regenerability of the filter cloth.

When installing the filter cloth, both sides of the seal lip should be embedded in the drum seal groove with the filter cloth seal ring supplied (for filter element of gravity discharge or scraper discharge centrifuge). Seal failure shall not exist, to prevent material leakage causing vibration.

The requirements of corrosion should also be considered in the separation of filter cloth material according to the chemical properties of the material to separate.

|

Performance |

Polyester |

Nylon |

Polypropylene fiber |

Vinylon |

|

Acid resistance |

Strong |

Poor |

Good |

Non-acid resistant |

|

Alkali resistance |

Weak-alkali resistant |

Good |

Strong |

Strong-alkali resistant |

|

Corrosion resistance |

Good |

Poor |

Poor |

Good |

|

Conductivity |

Very poor |

Relatively good |

Good |

Moderate |

|

Recoverability |

Very good |

The recovery rate is above 90% at 10% elongation |

Slightly better than the wheel |

Poor |

|

Abrasion resistance |

Very good |

Very good |

Good |

Relatively good |

|

Heat resistance |

130℃ |

120 ℃ slightly shrunk |

90 ℃ slightly shrunk |

100 ℃ slightly shrunk |

|

Melting point |

255-265℃ |

210-215℃ |

165-170℃ |

220℃ |

Before applied in food or pharmaceutical industry, rinse warm water, so as not to bring the dirt on the cloth.

Soldering by electric iron may prevent loose weft.

The sewing thread must be equipped with the same performance.

After the use of cloth, if the cloth holes are clogged so that the cloth is hardened, affecting the filtration rate, soak and wash the cloth with acetone, oxalic acid, toluene, caustic soda, alcohol and other solutions according to the properties, to soften the cloth, restore the hydrophobicity and breathability of the cloth, and improve the cloth usage.